Kobelco compressor Instruction Manual - AG370, AG610. Kobelco Kobelion II VS series Kobelco Kobelion II Oil-Flooded Screw Compressors achieves the maximum level of discharge volume and efficiency in its range.

Discharge air volume 10.5 - 49.3 m3/min(0.69MPa)

No matter what the load condition, Kobelco inverter control achieves ideal energy savings without unnecessary motor rotation. Instantly responding to any changes in demand pressure, pressure fluctuation could be minimized within ±0.01 MPa, thus supplying the required air volume with precisely controlled operating energy.

VLC for Mac OS X VLC is a free and open source cross-platform multimedia player and framework that plays most multimedia files as well as DVDs, Audio CDs, VCDs, and various streaming protocols. Vlc player for mac el capitan. VLC Media Player is one of the most-used media players now available, not just for its stability and versatility when it comes to playing all sorts of multimedia.

Equipped with the world's first IPM motor

Specifically designed inverter couple with IPM motor can make a power-saving effect that no-conventional inverter can make.

Capability for high pressure applications

Air cooled unit (0.88 MPa), water cooled unit (0.93 MPa) Numerology and the divine triangle by faith javane pdf to excel.

New Kobelion VS series offers maximum energy saving with minimum pressure fluctuation backed by own algorithm to run inverter of Kobelco as a pioneer of inverter compressor. New Wide Range Control In case that required pressure of compressor is 0.5MPa, you may be able to use one size smaller compressor. Contact Standard Compressor Global Operation Section Compressor Division Machinery Business Kobe Steel, Ltd. TEL:+81-3-5739-5342 FAX:+81-3-5739-5345. This course is designed for KNW compressor service personnel who are responsible for maintenance and equipment repair. This should be of interest to companies who own and operate a Kobelco KNW Series oil-free rotary screw compressor and are responsible for maintaining their compressed air system.

Line pressure control (Optional)

● Maintain a necessary pressure in the line

● The best energy saving operation is possible with an optimized discharging pressure

● Keep track of the pressure losses (losses in electric power consumption)

Kobelco Screw Compressor Manual Water Pump

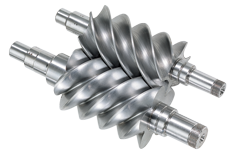

High performance screw unit

A completely new design of the two-stage compressor unit and a reduction in package internal pressure losses resulted in an energy saving by 8% over existing models.Furthermore, a plate-fin, the first in the industry, was incorporated for the water-cooled, inter cooler and after cooler, reducing the air pressure loss to 1/5.

Ultimate clean air

Kobelco Screw Compressor Manual Vacuum Pump

The oil-free design introduces absolutely no oil to the rotor chamber in the process. Stainless steel shaft-seal rings are used to prevent the generation of carbon dust, and KobelcoÕs patented twin atmospheric shaft vents prevent lubricating oil from contaminating the compression chamber even during extended periods of unloaded operations.

Improved maintainability

Capability with 1.03 MPa specifications

All models are equipped with a compressor main unit that can operate with a pressure of up to 1.03 MPa.

Improvement on durability for ambient

Alternate operation function of two units-Graph display of operating history, weekly timer, daily report management, maintenance information, and operation status.

Built-in Higher harmonic reactor as standard

* Complies with harmonic suppression guidelines by the Japan Electrical ManufacturerÕs Association (JEMA)

Soft start by KOBELCO inverter

Kobelco Knw Series Pdf

Totally enclosed fan-cooled motors are adopted to increase motor durability.

Protection features

Various improved protection for Electric parts.

Momentary interruption protection: Within 0.5 sec.The compressor unit does not stop even when an momentary power failure (momentary power interruption, momentary power drop, temporary blackout) occurs, as long as the interruption time interval is less than the set value. The compressor unit is stopped when the power interruption duration exceeds the set value.

Built-in 12,000-V lightning surge killer and noise filter.

Automatic reset from power failure: 0.5 to 20 sec.

Example: Setting for recovery after power interruption: 5 sec.; power recovery standby time: 15 sec.

Exhaust cleaner that requires no oil mist breather piping

This Exhaust Cleaner has its self oil separation and recovery function. This can prevent differential pressure increase and can realize long term maintenance interval.